3D printing: the high-tech hobby that is firmly within reach!

If you are looking for a hobby that will challenge and engage both your technical and creative abilities, you’ll be surprised at just how accessible and affordable 3D printing can be.

In just under a decade, 3D printing has gone from an obscure semi-industrial branch of design and technology to a mainstream recreation, with hobbyists often at the cutting edge of its innovation and creativity.

3D printing is a heady mix of Computer-Aided Design (CAD), problem-solving, art, and engineering that is on the rise in popularity across the globe.

It is also highly scalable with compact printers being set-up on the dining table to expansive, powerful, studio-sized 3D printing machines that can produce large-scale objects. For once, the limit really is your imagination!

In this comprehensive guide to 3D printing as a hobby, we will run through everything you need to know to get a 3D printing setup underway, and the types of interesting projects you can undertake once the basics are mastered.

We think that 3D printing is here to stay and is the perfect match for those who would enjoy turning their hand to a totally futuristic pastime, where you can make all sorts of things from the comfort of your home.

Read our 3D Printer Buyers Guide Here

What’s 3D Printing Then?

If you are wondering when printing leaped off the page, you will find that things have accelerated way beyond the Guttenberg printing press of 1440. Printing is now firmly operative in the third dimension, thanks to CAD and digitally controlled printing processes.

Also known as additive manufacturing, 3D printing involves the construction of 3-dimensional objects under digital or computer control. The design and structure for the created object come from computer-aided designs that are used to program a 3D-printer.

Alternatively, an object can be scanned by a 3D scanner and the resultant data used to program the printer to create a reproduction of the object.

What is a 3D printer?

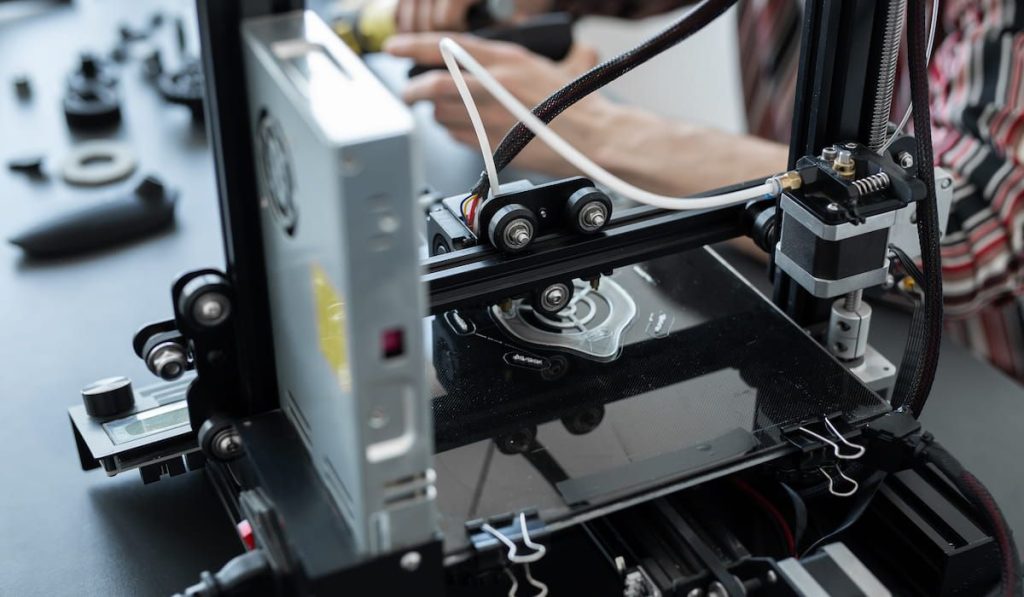

3D printers are digitally controlled printers that deposit material according to a pre-programmed design to create a 3-dimensional object. 3D printers don’t just move left to right, they move up and down too!

So, what you have is a printer that works on the X, Y, and Z axes. They lay down their material layer by layer, much like a regular paper printer deposits ink on paper.

Enterprising individuals have already been able to co-opt an old inkjet printer to print with materials other than ink!

The difference with a 3D printer is that the layers of material are built up, an additive process, to produce the finished object. If you think about it, it’s a totally new way of making 3D or solid objects.

Usually, we carve, mold, screw, or glue things together, but with a 3D printer digital file, the layers of the object are laid down, bit by bit by the printer.

The typical components of a hobby 3D printer include:

- A user interface, drivers, and file transfer connectivity: Your 3D printer can be connected to a computer or, like many hobby 3D printers, operate as a stand-alone unit. The tabletop versions usually have some sort of LCD or digital user interface with knobs or a dial, allowing you to control the printer’s settings directly. Most home 3D printers also carry a USB port for you to connect your computer or CAD files directly on the USB stick.

- The controller board: This is like the motherboard of the printer and has all the circuitry that pertains to translating the instructions in a design file into the actual movements of the printer. The quality of this component will directly affect the printer’s performance and the quality of the objects you make.

- An extruder setup: This part of the printer feeds the printing material into the print head. Your printer may work with one or two (dual extruder) feeder systems to channel material into the print heads.

- The filament is the material that is used to make your models. It is often ABS (Acrylonitrile Butadiene Styrene) that can be heated up for extrusion through the printhead and cools to form your solid shape. Spools of this material come in all sorts of colors and finishes and simply attach to your printer’s feeder system.

- The frame provides the structure on which the print head and other motion components can move to create the accurate movements and positioning needed to create the design. Metal frames are considered the most durable.

- Motion components include the mechanics (belts, rods, and end stops) and gears that affect the precision movements of the print head.

- The print bed is where all the action takes place. The printer will build up your 3D design on this surface. To prevent warping of a printed item, some print-beds are heated and in other printers, the print bed can be raised or lowered.

- One or more print heads. This is also known as the extruder and will deposit the modeling material in-line with the design file you supply. Solid thermoplastic is fed into heating components within the print head which are much like those of a glue gun. Hot, softened material can then be extruded onto the print bed and cooled by an attendant fan. Nozzles for this job vary in size and can be swapped in and out depending on the type of detail you need in your 3D design.

There are many ways in which 3D printers make objects and we’re sure that as you progress in your hobby, you will find the type of printing that works for you.

- Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF). This form of 3D printing uses extruded thermoplastic material wound on a spool in beads to form the layers that make up a printed model. The hot plastic immediately hardens to form the layers of the design.

- Multi-jet modeling or 3D inkjet printing is similar to inkjet printing but replaces toner with a binding compound that works on layered, powdered plaster or synthetic resin out of which the model is built in layers.

- Stereolithography involves a liquid material that is cured by UV light passing over it in specific places to produce the finished solid object. The UV light moves following the CAM file directions for the design of the object.

What Can You Make with a 3D Printer?

In the case of 3D printing, the limit is your imagination, with hobbyist projects ranging from the wacky and zany to surprisingly functioning items that can solve practical problems.

A great example is this Isle of Wight, UK resident who used a 3D printer to create face shields for members of his community. As with most hobbies, from starting simply you can quickly build expertise to make some very interesting items including:

- A digital sundial (well worth checking out!)

- Toothpaste tube squeezer

- Handy measuring cubes

- A megaphone

- A battery-powered LED lamp

- An electric guitar body

- A combination lock

- A wallet

- Kitchen sink drainers

- A functional computer keyboard!

9 Reasons to make 3D Printing Your Next Hobby!

If you aren’t sold after seeing the fantastic projects you could be making with your new 3D printer, here are some great reasons to make 3D printing a lasting hobby:

- It’s a creative hobby that does not require you to have an aptitude for art.

It’s great that with 3D printing you do not have to be gifted in sculpture or the other creative disciplines to create something amazing! Once you get to grips with the basics of using a 3D printer, experimentation is the rule of the day.

Hopefully, once you master making 3D printed projects from template files, you can start to get to grips with the basics of designing your custom items and creating the necessary CAD files.

- STEM friendly hobby for children.

3D printing is perfect for children and young people who enjoy science and technology. Even if these are not initially strong subjects, using 3D printers will stretch their non-verbal reasoning, logic, and spatial skills and exercise mathematics and engineering when they start to code their designs. It’s also great for a rainy day as it will keep them safely occupied for hours.

- Great technical and electronics skills.

If you don’t want all your technical experimentation happening on a computer screen, a 3D printer is a fantastic way of making the techie world more practical.

A 3D printer can be a springboard for all sorts of electronics projects, for example, this glam 3D printed sequin clock. Printing components that can be put together to make mechanical and electronic devices will certainly get the most value out of your 3D printer.

- Make useful things for your home – save money.

Once you start exploring the world of 3D printing you will be surprised at just how many items you can print for your home. 3D printing has a community of innovators who are adept at producing high-quality print files for just about anything.

Broken appliance components or parts can be scanned, and 3D printed, saving on the expense of a replacement or for repair. When you can just make your bottle opener, ice scraper, desktop organizer, or vase in minutes with your 3D printer, you can give the shops a break and save some money too.

- Is 3D printing your next side hustle?

When you see just how productive you can be with a 3D printer you will soon be asking yourself this too. After all, 3D printing is a form of manufacturing. Hit on the right useful design and you could find yourself with a hobby that at least earns its keep. Most 3D printing hobbyists earn their income in one of three ways:

- Sell printed objects. Vases, earbuds, and PC tower casing are all premium products that 3D printing hobbyists are selling online right now via sites like Etsy or eBay.

- Offer a 3D printing service locally. Local designers and architects may call on your services to produce scale models or prototypes.

- Sell original downloadable CAD print files for other hobbyists to use. If you master a great design, you can sell the print file via several dedicated online platforms.

- Become an inventor.

Professional 3D printing plays a big part in product development and creating prototypes for the manufacturing industry. If you are a hobby electronic or mechanical engineer, a 3D printer is a great piece of kit for your workshop.

For budding designers, 3D printing is soon going to be the critical first step to getting a product off the ground and attracting the attention of potential manufacturers and investors.

- Your hobby may be a first step to breaking into a growth industry.

Launching a career in 3D printing will certainly be helped by you actively doing it as a hobby. You may have started hobby 3D printing at your desk or tabletop but as a 3D printing technician, you could find yourself building the next space shuttle, medical innovation, or sports car.

- May help you create parts for other hobbies.

If you have a hobby that uses a lot of consumable parts, like wheels or propellers, investing in a good 3D printer can equip you to make them yourself.

- Indoor activity

3D printing is a great indoor hobby, especially as most of the equipment and components can be readily purchased online. A rainy afternoon can easily be passed in priming and programming your printer to complete several small projects, or fabrication of individual components for a bigger or more complex structure.

Is 3D Printing an Expensive Hobby?

For most people, 3D printing sounds pretty exciting but as with many technical hobbies, the cost is a major consideration.

The good news is that all the ‘big spending’ is upfront, with consumables such as the reels of filament, tape, and sandpaper being relatively cheap.

The price of a home 3D printer can vary massively, from a few hundred dollars to thousands of dollars.

The cost of a 3D printer is not directly related to its size; the specifications and performance profile of your printer should be taken into consideration.

As hobby 3D printing is relatively new, there is less opportunity to scour the classifieds and thrift stores for second-hand equipment, which also may be faulty.

This Reddit thread run by hobby 3D printers should provide some real-world insights into just how much you will be spending to maintain a 3D printing hobby.

What You Will Need to Get Your 3D Printing Hobby Workshop off the Ground

One of the best things about a new hobby is all the cool gear you need to make a success of your interest. With 3D printing, the tools of the trade will determine the quality of the results you have, and if you want to put printed components together you will soon find yourself amassing a mini workshop of equipment for the job. Here are the absolute essentials for starting 3D printing:

Your 3D printer: Once you have settled on the type of printing you want to do and the size of the models you will be making, you will need to look for the right printer.

Evaluating the best 3D printer for hobby printing is beyond the scope of this article, but key features to look out for in a home 3D printer include:

- A generous print volume

- A heated print bed

- Good support, spare parts, and warranties from the manufacturer

A laptop or desktop computer: Before rushing out to buy a new MacBook, it’s important to stress that the STL files that are commonly used for 3D printing are usually below 20 MB, so operating your printer should not be too much of a challenge.

However, if you want to design objects, you may need a computer with adequate memory, processing power, and decent screen resolution. Doing all the number-crunching needed for decent CAD can devour CPU, so a dedicated PC may be the way to go.

3D printing software: 3D printing software allows you to modify and design your printed models. Thankfully, there are lots of good quality open-source software for 3D printing, which means that you can get to grips with producing your designs without eye-watering subscriptions.

Look out for Ultimaker Cura, OpenSCAD, FreeCAD, or TinkerCAD which are accessible and suitable for modelers of all levels of expertise.

Filament reels: These will be your number one consumable and determine the color and finish of your model. Filament comes in a range of colors and can even be infused with wood dust or cork for a finish that is easy to sand. Quality can vary greatly so it is well worth experimenting with a variety of brands until you settle on a material that works well with your printer.

Sandpaper: A completed model will need post-processing with sandpaper to get the best finish. You will need several fine-grit grades to get your objects fully smoothed.

Masking tape: Those ‘in the know’, use masking tape to cover the print bed of their 3D printers as it helps the 3D model adhere properly. It is likely to need regular replacement, so a wide tape provides quicker coverage. A more expensive alternative covering for your print bed is heat resistant Kapton tape.

Tweezers and pliers: These do a great job of removing oozing and crusting material from your printer’s nozzle. Keep them on hand to remove strings and blobs from your completed model. They can also come in handy for spot repairs to the printer.

Craft knives: A sharp knife is ideal for finishing your model and neatly removing excess material.

An airtight container and desiccant for storing filament: If you leave your filament in the open air, you may find that the quality deteriorates with time. Proper sealed storage prolongs the life of your filament and prevents damage to your printer from a degraded material.

BYOP: Build Your Own (3D) Printer

This hobby can be extended even further by taking on the challenge of building your own functional 3D printer. If you have a passion for building something with your hands from scratch, building a printer is a satisfying challenge.

One of the benefits of making your own 3D printer is that it can be built to any size. It will also help you in making repairs to your printer as you will have a good understanding of how it operates.

3D printers were originally custom-built, with wooden frames and plenty of exposed wires, as designers worked on developing this new form of manufacturing.

You can either amass the components and follow one of the hundreds of detailed tutorials available online or purchase a 3D printer kit that comes complete with everything needed to produce a printer that actually prints!

A Quick Glossary of Key 3D Printing Terms

- 45-degree rule: The 45-degree rule is used by modelers to avoid designing parts of objects that overhang and could collapse under their weight. Modelers should avoid designing objects with angles greater than 45 degrees without a support material to prevent collapse.

- ABS: Short for Acrylonitrile Butadiene Styrene, a non-biodegradable thermoplastic commonly used in FDM 3D printing. It is available in filament form on spools.

- G-code: A CAD programming language used to code 3D designs in 2D layers. The movements of the 3D printer are directed by G-code.

- Slicer: This is a 3D modeling software that takes 3D image files and slices them into 2D layers (G-code) so that they can be used by your 3D printer

- STL file: (Standard Tessellation Language) This is the native file type for 3D designs and can be created on specialist 3D design software.

- Support material: These materials are included in design projects which have a significant overhang or angle greater than 45 degrees. They support the overhanging structure. Support materials should be able to be easily removed (usually by dissolving it away) after the object is completed.

Quick Links and Resources for Hobby 3D Printing

The Tabletop 3D Printing Guild: A members-only Facebook group for 3D printing hobbyists.

3D Printboard: An online forum with message boards for tips and tricks for 3D printers.

Make Anything: One of the leading YouTube channels for hobby 3D printing.

Starting 3D Printing as a Hobby Round-Up

We hope you have enjoyed this guide to 3D printing as a hobby. Think of it as a springboard to the further research you will need to do to make a real success of your new hobby.

If you are already a seasoned hand at 3D printing, do you have any advice to share with newbies? If so, we would love to hear from you. Share your thoughts in the comments section below!