There are so many production hobbies. Knitting, Resin Casting, and now 3D Printing, just to name a few. Each method has a very unique outcome; knitting for blankets, sweaters, and other soft items, resin casting for hard, sturdy pieces, but where does 3D printing fit in? How strong are things made on a 3D printer?

In short, it depends. It depends on what type of machine you use and what materials you use. But it mostly depends on your design. A weak design will lead to a weak product, but there are things you can do to make it stronger!

Type of Printer

The type of 3D printer plays a huge role in determining the strength of an item.

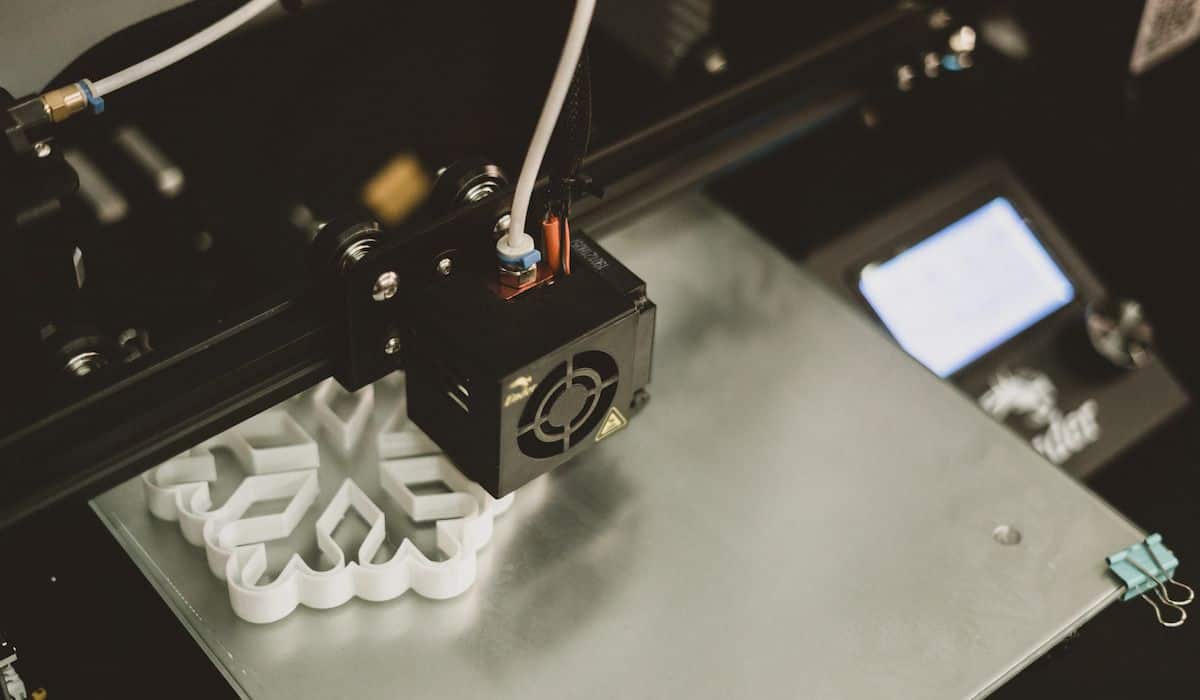

Fused Deposition Modeling (FDM) machines melt down a plastic and deposit it layer by layer.

While the nozzle melts the plastic there is a fan that cools the plastic to keep it in place instead of melting further. This gives a solid base for the next layer to sit on.

The other type of 3D printer is a resin printer. This isn’t as strong as cast resin because it is also made in layers, but this is stronger than FDM 3D printing.

Click here to view our complete guide to 3D printing as a hobby.

Type of Material

The strength of an item also depends on the type of material used.

There are three main types of materials used for FDM machines, Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), and Polyethylene Terephthalate Glycol-Modified (PETG). The strength of a material is measured in tensile strength, which is the amount of tension required to break the material.

PLA – Polylactic Acid

PLA is the most common 3D printing material, but it is also the weakest. This is the material that gives 3D a bad reputation when it comes to the strength of a material.

The tensile strength of PLA is 7250 psi, which is considered very strong. Despite the tensile strength, it’s weak because it’s very brittle.

It breaks under much less force. PLA also has a very low melting point, so any increase in environment temperature can weaken the material.

ABS – Acrylonitrile Butadiene Styrene

ABS is a weird material, because it has a lower tensile strength than PLA at 4700 psi, but it is much stronger.

ABS is able to withstand much heavier impact before it breaks.

PETG – Polyethylene Terephthalate Glycol-Modified

PETG is one of the best 3D printing materials. It is denser and much more durable than either PLA or ABS with a tensile strength of 8500 psi.

If you’d like to see how each of these materials perform under pressure, check out this video.

Print Design and Orientation

You’ve already bought a 3D printer, you’re using ABS, and your prints don’t seem to be strong enough for what you need them for. What now?

Thankfully, there are ways to make your 3D prints stronger. By using the same material as you were before, just making a few modifications, you can drastically increase the strength and stop making fragile pieces.

Imagine building a house, but only by gluing some sidings together, and throwing some shingles on top. Would you live here? Probably not, because you know it’s not very stable. How do we fix this? With walls and infill!

Walls

Your house and design need some walls. By creating support walls on the inside of your structure you instantly add much more support.

You’ve given your sidings something to attach to, thus making it sturdier.

Infill

Now you need some support under those walls! The space between walls is the infill for a 3D print.

Imagine this as your frame, your studs, and your insulation. The more you put in there, the sturdier and better your home – or 3D printing project – will be.

Printing Orientation

You can’t build a house upside down, so that metaphor stops here. But knowing a 3D printer works from bottom to top in layers, you can orient your 3D design to print in different ways to make your structure stronger.

Instead of printing from the bottom of your design to the top of your design, try lying the design on its side before printing so it prints the entire height along the printing mat, and prints from side to side.

To see this in action, check out this video on how orientation changes the strength of an object.

Wrapping It Up

3D printed items are not strong. The method of heating and cooling plastic in layers makes thin items quite easy to break.

However, by changing the materials you’re printing with, and by putting some more time into the design, you can significantly increase the sturdiness of your 3D printed items.

If that still doesn’t work, try changing the 3D print orientation on your printing mat.

Once you’ve figured it out, you can have a plastic piece that is stronger than metal.