Knowing the cost of a hobby is something many people consider before getting into a new hobby. After all, if you’re worried about how much something is costing you, are you really going to enjoy it? With that being said, you must be wondering how much does it cost to 3D print?

The real answer to this completely depends on what you’re making, what printer you’re using, and how big the project is.

The cost to 3D is an investment upfront for the machine and your time learning your new craft. If you want to try 3D printing, you can get started for under $300 for a home hobby machine. Materials will cost around $60 and an online course to learn will cost $20-99

All of this will be broken down in this article to give you a much better idea of how much it costs to 3D print.

What Printer You Use

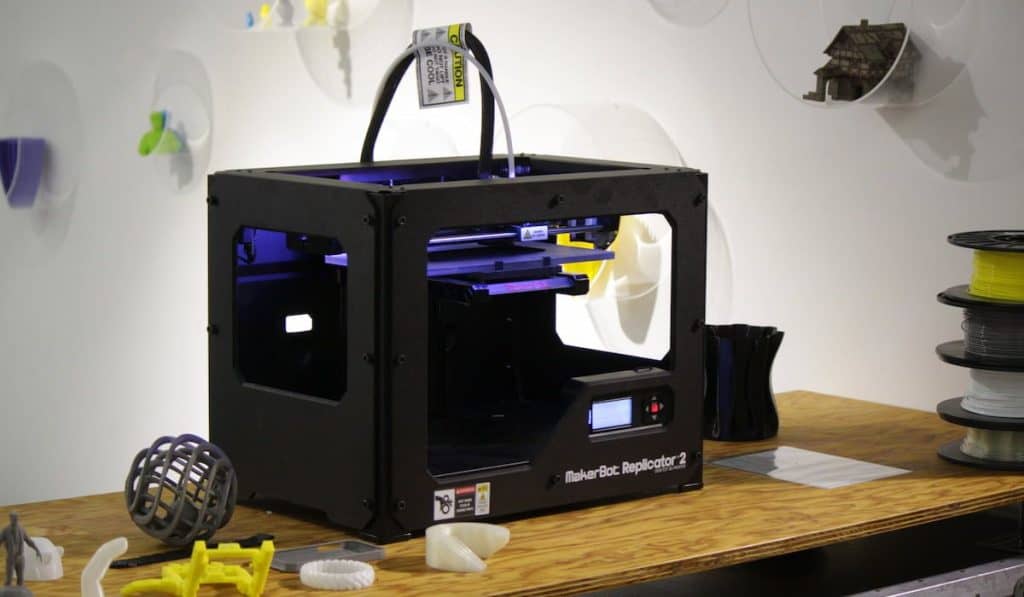

The very first cost you must consider is the printer itself. Prices vary quite a bit with 3D printers.

If you are looking for a very basic 3D printer to get started with some trial projects, a 3D printer can cost as little as $200. If you’re looking for a more reliable machine, you’re probably looking at an investment of $500.

If you are looking for a very advanced 3D printer, you could be spending upwards of $6000. Like most things, you get what you pay for, but that doesn’t necessarily make the more expensive machine is better.

With higher-end machines, the technology is likely to be more advanced, can use a wider variety of materials, often has upgrade capabilities, might have better support if you run into troubles, but both high-end and low-end machines will work.

The Size of Your Project

When trying to figure out how much it costs to 3D print, you need to take the size of your project into account. 3D printers at home usually have a 12”x12”x12” printing size and all sorts of print sizes can fit in this space.

If you were to make a small, single-layer item like a keychain, you might only pay $1 in thermoplastic material. If you were to make something the size of a football out of the same thermoplastic, you might pay about $100 in material.

Wall Thickness and Infill

The other thing to consider when determining the cost to 3D print is the thickness of the walls of your project, or the infill.

Imagine for a second the amount of material needed to make a hollow basketball. Now think about how much material would be needed to make a bowling ball. One is filled with air, and the other is completely filled with material.

The same goes for projects done on a 3D printer. If the shape you are printing is hollow, you are going to use less material than a shape that is completely filled (100% infill), or even something with thicker walls (20% infill).

Did you know you can actually print a full-size car on a 3d printer? Check out all the facts here.

Type of Material

The type of material matters too. The different types of filament come with their own price tag.

The cheapest filaments are the PLA and ABS thermoplastics . These are the most common materials for 3D printing at home.

Nylon materials will come with a higher price tag but will also provide a much stronger final product. This material is mostly used in construction manufacturing because of its strength.

You might consider the environmental cost of 3D printing. If you want to print with environmentally friendly materials, these will cost more than any other materials because they can’t be produced as easily.

Running Costs

3D printers need electricity to run. If you don’t live off the grid and rely on solar panels, you have to pay for that electricity to run your machine.

The temperature you set your hotbed and nozzle to will also determine how much power your 3D printer will need.

If the hotbed is set to the normal 400°F and nozzle to 140°F, a 10-hour print will use about 0.7 kWh which will cost around 9 cents depending on your location.

Final Thoughts

There are many things to consider when you are trying to find the cost of 3D printing. The size of the project and the amount of infill for the project will help you determine how much material you will need and how long the machine will need to run.

Once you know how much material you need, you can decide what type of material you need for your project.

If you want to price out how much a specific project would cost, you can check out this website. It uses the cost of your filament, the measurements of your project, and the time it takes to print your project to come up with an estimate on how much it will cost.